An EDC knife is the most frequently used among the vast options of EDC tools. The right EDC knife is crucial for outdoor adventures, everyday tasks, or specific activities like setting up camps, cooking outdoors, etc. In this blog post, we’ll focus on the specific needs and considerations when choosing an EDC knife tailored for outdoor use. From camping to hiking, having the right EDC knife can significantly enhance your outdoor experience.

What Should You Consider When Choosing an Outdoor EDC Knife?

Nowadays, our lifestyle is more prone to nature. Outdoor activities have become trendy and a part of a lifetime. EDC gear is gaining popularity as it facilitates us in implementing tasks and enhances our outdoor experiences. There are endless options for outdoor EDC knives in style, brand, materials, and functions. Whatever your preferences, you should consider the following factors while choosing your outdoor EDC knife.

Blade Material

Superior blade materials are typically known for their enhanced durability and extended edge retention. At Keygadgetry, our website provides top-notch materials like titanium, stainless steel (8Cr13MoV), and carbon steel to ensure high quality and long-lasting performance.

Blade Hardness

For outdoor use, the ideal range of blade hardness for a knife typically falls between 55 and 62 HRC (Rockwell Hardness Scale). Here’s why:

- 55-58 HRC: Blades in this range offer durability and are easier to sharpen. They can endure more demanding tasks without chipping or breaking, making them suitable for outdoor use.

- 58-62 HRC: Blades in this range hold an edge exceptionally well, making them suitable for tasks that require a sharp edge for a longer period. However, increased hardness makes them slightly more prone to chipping or breaking.

Blades within this range are durable enough to handle most outdoor tasks, such as cutting rope, preparing food, and carving, while maintaining a sharp edge. It’s important to remember that harder blades hold an edge longer, but they can also be more difficult to sharpen and more prone to chipping or breaking under extreme stress. Therefore, it is essential to balance durability and edge retention.

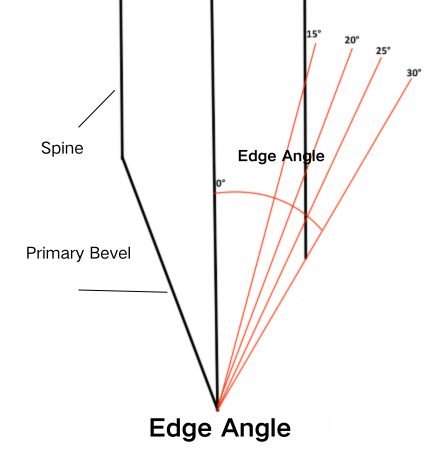

Edge Angle

The edge angle is the angle at which the cutting edge is crafted into the side of the knife to create a sharp tip. This measurement extends from the knife’s centerline to the spine’s outer edge.

A pocket knife with an edge angle of 17-25 degrees to both sides is adequate for outdoor tasks like opening boxes and cutting ropes. However, for more demanding camping or hiking activities such as trailblazing and wood splitting, opt for an edge angle of 25-35 degrees. It’s important to note that thinner angles result in sharper blades but may compromise durability.

Blade Shape

Blade shape is not just about style; it’s a critical factor in determining the knife’s efficiency. It gives the knife its character, strengths, and how it performs in your hand.

The curve, angle, edge, and bevel contribute to the knife’s performance under various circumstances.

To attract consumers, manufacturers continue to present new knife blade shapes. The following ten major blade shapes are widely used in outdoor EDC knives and focus on several applications.

Clip Point

A clip-point blade is characterized by a concave or straight cut-out at the tip, creating a slightly upswept, clipped point. This distinctive clip design allows for a more acute point, providing excellent control and piercing capability, such as skinning and fine detail work. It is very popular among hunters, outdoorsmen, and everyday users.

Disadvantage: narrow tip, which tends to be weak and can break fairly easily

Drop Point

A drop-point blade is characterized by a convex spine curve that gradually descends from the handle to the point, creating a lowered or “dropped” point. This design makes a strong, robust tip less likely to break during heavy use. A drop-point knife is an all-purpose blade used in many situations, such as tactical, survival, and hunting knives.

Disadvantage: The broad tip is not as sharp as the clip-point blade, which is less sufficient for the piercing.

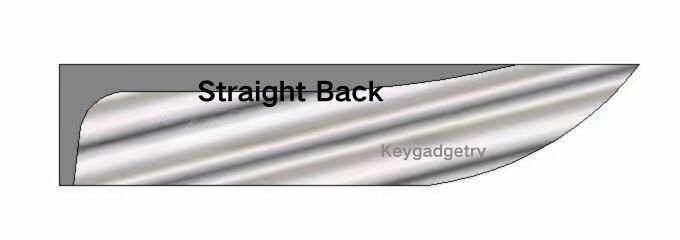

Straight Back

It is a standard-style blade that can be traced back a thousand years. With a straight spine and a standard belly, it wasn’t designed for any specific purpose, making it versatile and particularly useful as a survival knife.

Trailing Point

The trailing point blade has a curved spine that extends straight out of the handle and sweeps upward to form a trailing tip. The trailing tip creates a large, curved belly, making it ideal for skinning and slicing. The sharp tip allows for precise and detailed work. It is a great tool for outdoor cooking, assisting in tasks such as slicing fillets or meat.

Disadvantage: The thin blade and sharp tip are susceptible to breaking when working with hard materials.

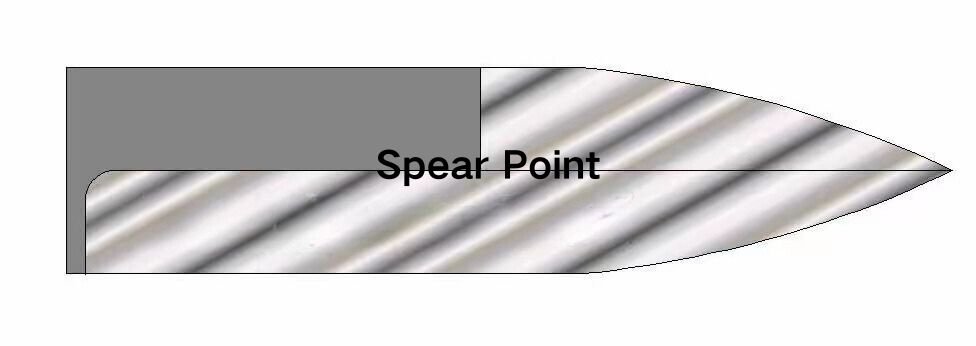

Spear Point

A spear point blade is symmetrical, with the tip in line with the center of the blade’s axis. It can be single or double-edged. This hybrid design is extremely functional and perfect for those seeking the balance between piercing and slicing.

Disadvantage: small cutting belly; It is only good for piercing if both edges are sharpened.

Dagger

A dagger has a symmetrical design, similar to a spear-point blade. Sometimes, they are interchangeable. The main difference lies in the top edge. A dagger is sharper at the top edge. It is usually used as a defense weapon.

Disadvantage: It has few practical uses. Before carrying a dagger, check the local law or regulation for legitimacy.

Sheepsfoot

A sheepsfoot blade is identified by its straight edge and a dull spine that runs parallel to the edge before curving steeply downward to form a tip where it meets the edge. It was originally intended for the shepherd to trim the sheep’s hooves. The blunt edge ensures safe cutting tasks, reducing the risk of accidentally puncturing or injuring people. It is ideal as a rescue tool for marine applications or any cutting task requiring no piercing.

Disadvantage: It cannot perform tasks that involve piercing.

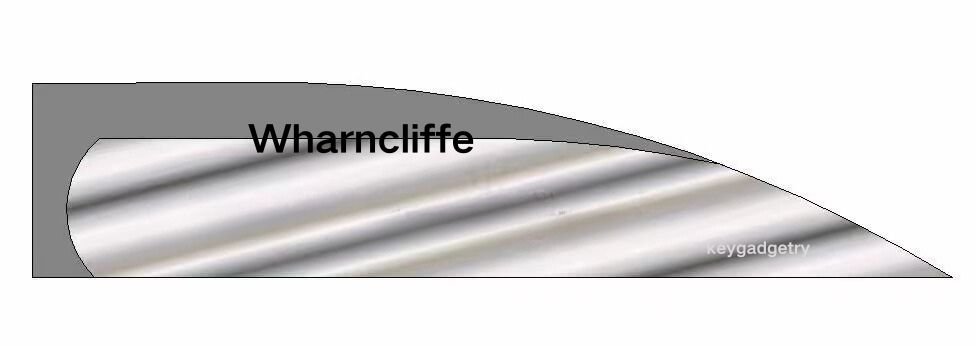

Wharncliffe

A Wharncliffe blade is named after Lord Wharncliffe, a 19th-century knife factory owner. It is a variation of the Sheepsfoot blade, featuring a gradual spine curve and a sharper tip. The straight cutting edge ensures a clean cut. The short blade and fine tip allow for rough carving and precision work.

Disadvantage: It is not ideal for chopping or deeply slicing into thick or fibrous materials due to its straight edge and lack of belly.

Hawkbill

A Hawkbill blade, also called a “ talon blade,” is characterized by its spine and edge curving downward in the same direction to create a point lower than the cutting edge. It is widely used for cutting carpets, cords, and plants.

Disadvantage: It is not a versatile EDC tool and may require professional sharpening due to its inward cutting edge.

Tanto

Tanto blades are inspired by the short swords worn by the Samurai of Feudal Japan. Their iconic angular point creates an aggressive tip, perfect for stabbing, piercing, and all-around self-defense.

Disadvantage: It is not as adept at slicing.

Locking

Most Outdoor EDC knives are portable. Despite their small size, the locking mechanism of an EDC knife cannot be compromised because it is for the safe opening/closure of the knife, as most EDC knives have sharp blades. Four types of locks are widely used among the majority of EDC Knives.

Liner Lock

The liner lock mechanism is a common locking system used in pocket knives. It consists of a side liner within the handle that moves into place behind the blade when the knife is opened. This liner prevents the blade from closing accidentally during use. To close the knife, the user must move the liner to the side, allowing the blade to fold back into the handle

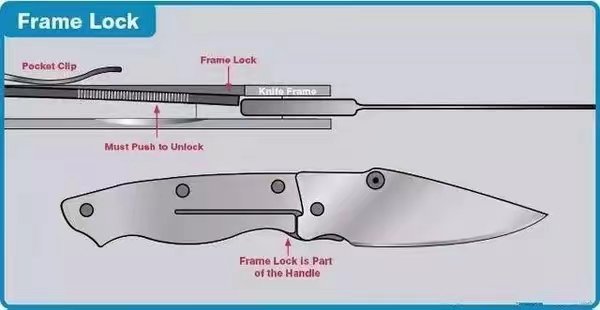

Frame Lock

The frame lock works like the liner lock. The difference is that instead of a liner being placed between the scales, the frame has a built-in spring acting as a liner. This type of locking is seen in many upscaled EDC knives, particularly made from Titanium.

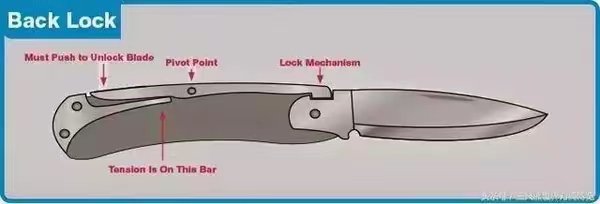

Lockback

Lockback locking features a notch on the back of the blade, which, when opened, engages with a spring-loaded metal bar within the handle. This mechanism prevents the blade from closing accidentally during use. To close the knife, the user must press down on the metal bar, releasing the blade to fold back into the handle. The well-known Spyderco knives have such a lockback system in their products.

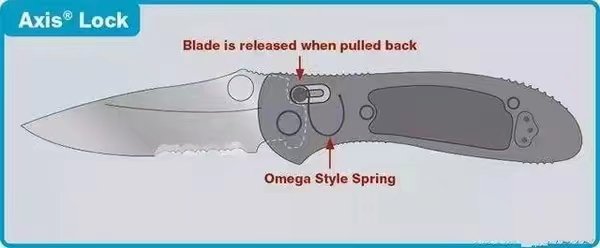

Axis Lock

The Axis Lock is a patented locking mechanism primarily used in pocket knives, notably associated with Benchmade. This mechanism employs a spring-loaded bar that slides back and forth in a slot cut into the knife’s handle. When the knife is opened, the bar snaps behind the blade, preventing it from closing unintentionally. The user pulls the bar back to close the knife, allowing the blade to fold back into the handle.

Handle

When considering an EDC knife, the handle material is crucial. The best materials include titanium, G-10, carbon fiber, micarta, and reinforced polymers. These materials resist corrosion and offer excellent grip experiences, ensuring a secure hold even in wet or challenging conditions.

Local Law and Regulations

An Everyday Carry (EDC) knife, especially a tactical knife, can be useful for various tasks. However, it’s important to note that different countries have varying laws and regulations regarding carrying such blades. It is advisable to thoroughly check the restrictions and laws in your area before carrying any type of blade in public. Being aware of these regulations can help you avoid potential legal issues and ensure that you are using your EDC knife responsibly and within the confines of the law.

FAQ

Knife blade hardness measures a knife blade’s resistance to deformation or wear. It is typically measured on the Rockwell Hardness Scale and indicates how well a blade can retain its sharp edge and withstand cutting tasks without chipping or dulling.

Blade toughness refers to a knife blade’s ability to resist fracturing or chipping when subjected to impact, lateral force, or bending. A blade with high toughness can withstand demanding tasks without breaking or sustaining damage, making it reliable for heavy-duty use.

Knife corrosion resistance refers to the blade’s ability to withstand rust and degradation when exposed to moisture, salts, or acids. Materials like stainless steel and certain coatings enhance a knife’s corrosion resistance, ensuring longevity and easy maintenance.

Knife wear resistance is the ability of a blade to withstand abrasion and maintain its sharp edge over time. A knife with high wear resistance will retain its cutting performance for longer without requiring frequent sharpening. Materials like high-carbon steels or certain alloys are known for their superior wear resistance, making them suitable for heavy use and prolonged cutting tasks.

Knife edge retention refers to the ability of a blade to maintain its sharpness and cutting performance over time and through repeated use. A knife with high edge retention will stay sharp for longer periods before requiring sharpening or honing. Factors that contribute to good edge retention include the type of steel used, the blade geometry, and how well the knife is maintained.